Many of us are now aware of the problems that plastics pose on our planet. One of the positives of PET, however, when compared to other synthetic materials, is that it is fully recyclable. It is possible to reduce the environmental impact of synthetic textiles by sourcing products that are made from 100% recycled material and here at YLX we make use of recycled PET (from plastic bottles) to make all our bags and accessories.

Choosing recycled polyester textiles can reduce the amount of plastic that ends up in a landfill. According to a study by the Swiss Federal Office for the Environment which was released in 2017, recycled polyester production also requires 59% less energy than virgin product. WRAP estimates that recycled PET production reduces emissions compared to virgin polyester production by 32%.

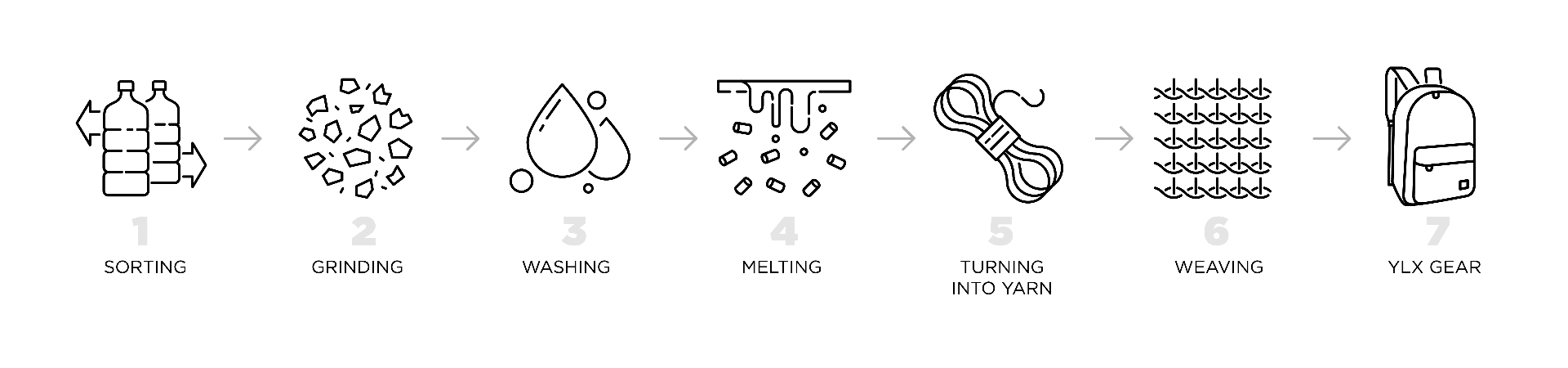

There are two means of recycling polyester. The first is mechanical. In this method, collected and crushed PET plastic bottles (or polyester textiles) can be used to make polyester fabrics. The second is chemical and involves returning waste plastic products to their original monomers, which can then be reused to make polymers in the virgin process. Let's take a look at the basic process, right through from collecting the plastic bottles, to the finished products.

Collecting Plastic Bottles

The first stage of the process is collecting the plastic bottles that are used. The plastic bottles can be collected from recycling points or recycling centers. The closer the collection points are to the point of reuse, the more sustainable the process will be, since the carbon costs of transporting the bottles will be reduced.

The Sorting & Grinding Process

The collected bottles are then sorted and graded according to color and other properties. Any non-PET plastics are removed, and any debris that has entered the waste stream is filtered out. The plastic bottles are ground down to make PET flakes. These tiny pieces of plastic are carefully sifted and sorted, then continue on to the washing and separation phase of the process.

The Washing and Separation Process

The pieces of PET plastic are carefully washed and separated to make sure that there are no impurities left within the material. They are washed and sterilized, and then dried to make sure that no moisture or other contaminants are left.

(In chemical recycling, the chips are de-polymerized and re-polymerized using chemical processes and formed into chips before passing on to the next stage of the process.)

The Plastic is Melted and Filament is Made

The small chips of clean, dry plastic are heated up and passed in viscous form through a machine known as a spinneret. This machine extrudes the plastic to form long filaments. These long filaments are wound up in spools.

Polyester Fibre is Turned into Thread

But the filament is not yet ready to be used as thread. The filament is now torn apart into short pieces to create staple fibers. At this point, the material looks a lot like sheep's wool. (It may go through a crimping machine at this stage.) This woolly material is baled. It then goes through a process called carding, which aligns all of the fibers so that they are pointing in the same direction. Finally, the fibers will be passed through a spinning machine that will turn those fibers into thread, or yarn.

The Threads are Woven into Fabric

Finally, the recycled polyester yarn is ready, and it can be woven into fabrics. These fabrics then go on for further processing. They are often dyed. In order to establish the sustainability of the product, it is important not only to look at the process of making the materials it is made from, but also to look at what other dyes and chemicals are used in order to complete the finished product.

Fabrics are Sewn Together and The Final Products are Made

Finally, the pieces of recycled polyester fabric, which may have been dyed, are ready to be sewn together to make the finished products. Recycled polyester may also be used in the thread used to join the fabric pieces together. Once they have been put together, and quality checked, the final products are ready for distribution and sale.

Understanding the processes that have gone into making recycled polyester products can help you to make the right decisions as a consumer. It can help you move gradually towards a more ethical and sustainable way of life.

United States, EN (USD)

United States, EN (USD) Europe (EUR)

Europe (EUR) Netherlands (EUR)

Netherlands (EUR) France (EUR)

France (EUR) Spain (EUR)

Spain (EUR) United Kingdom (GBP)

United Kingdom (GBP)